The Moore tube, introduced in 1895, was a carbon dioxide-filled tube up to sixty metres long, which gave a white light. The very long tube was not suitable for general illumination, but after 1905 the tubes were shaped into letters for illuminated advertising.

Nitrogen tubes which gave a pink light were introduced at about the same time, while red neon lights were introduced in 1910.

Such lights were not widely used until the 1920s. The first low-pressure mercury arc lamp was developed by Peter Cooper-Hewitt in 1901, but it was never widely adopted.

In the 1930s, however, the high-pressure mercury vapour lamp, operating at about atmospheric pressure was introduced. The types of glass then available could not withstand the operating temperature.

It was found that quartz was suitable because it has a higher melting point than glass and can be moulded into a strong vessel, but new manufacturing techniques were required since it behaves differently from glass when heated.

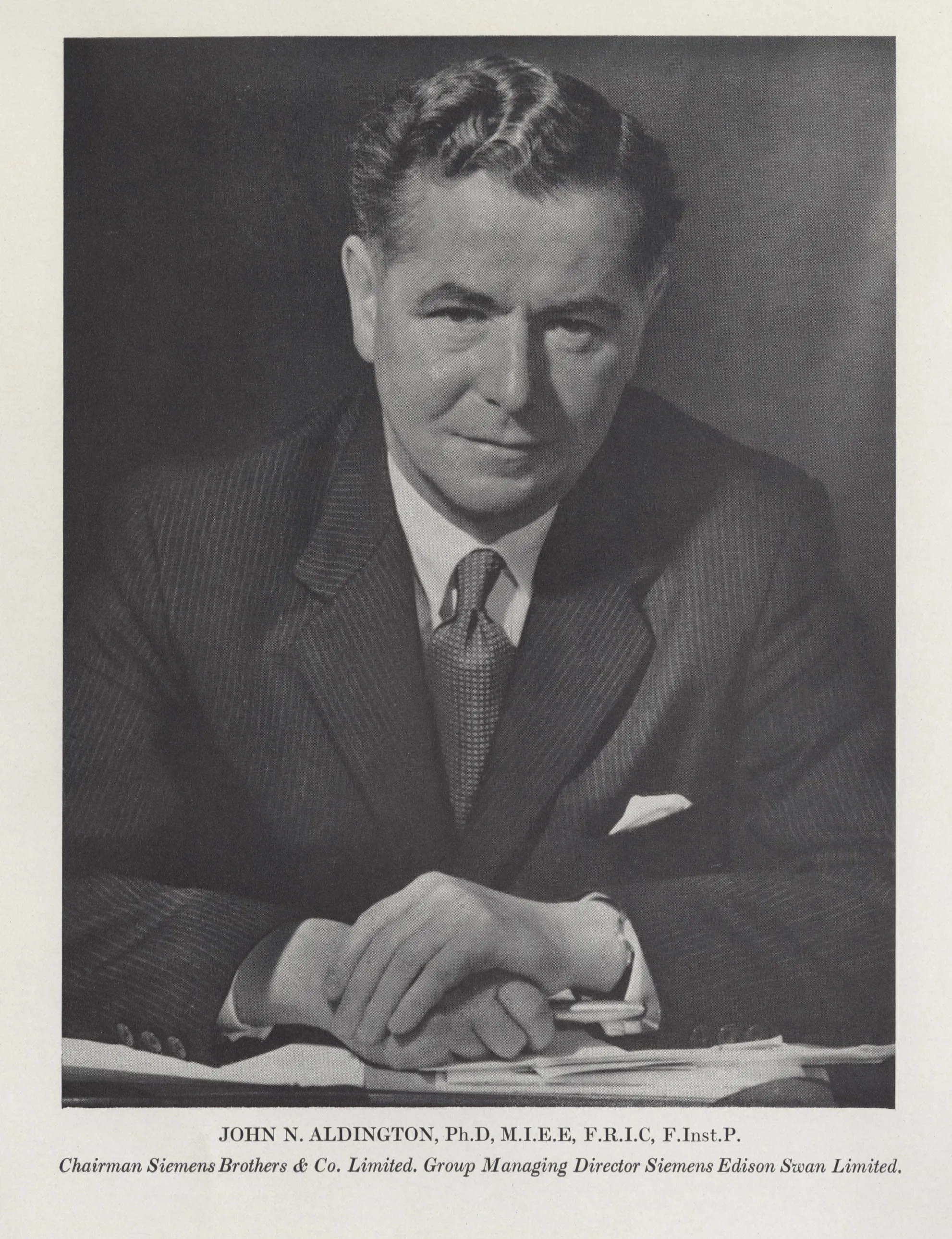

John Aldington

It has a much lower coefficient of expansion than soda glass and therefore does not crack when heated or cooled rapidly. New methods had to be found for sealing in the connecting wires. Platinum lead-in wires had been used in the earliest filament lamps because platinum and soda glass have almost the same coefficient of expansion. Subsequently, cheaper alloys were developed.

These alloys will not make a satisfactory seal through quartz because the alloy will shrink on cooling while the quartz maintains its dimensions, thus breaking the airtight seal. The first solution was to use thin molybdenum wires for the purpose, as these can be sealed satisfactorily through quartz. However, if thicker wires were required to carry higher currents, the seal was no longer satisfactory.

John Norman Aldington, working during the 1930s in the Siemens and English Electric Lamp company laboratory in Preston, Lancashire, found that he could obtain a good seal with a thicker molybdenum wire, if the wire were rolled flat at the point where it was sealed through the quartz. This technique is still used in the manufacture of high power mercury vapour lamps.