What is systems engineering?

The International Council on Systems Engineering (INCOSE) defines systems engineering as “a transdisciplinary and integrative approach to enable the successful realization, use, and retirement of engineered systems, using systems principles and concepts, and scientific, technological, and management methods” [9]. INCOSE defines a system as “a combination of interacting elements organized to achieve one or more stated purposes”.

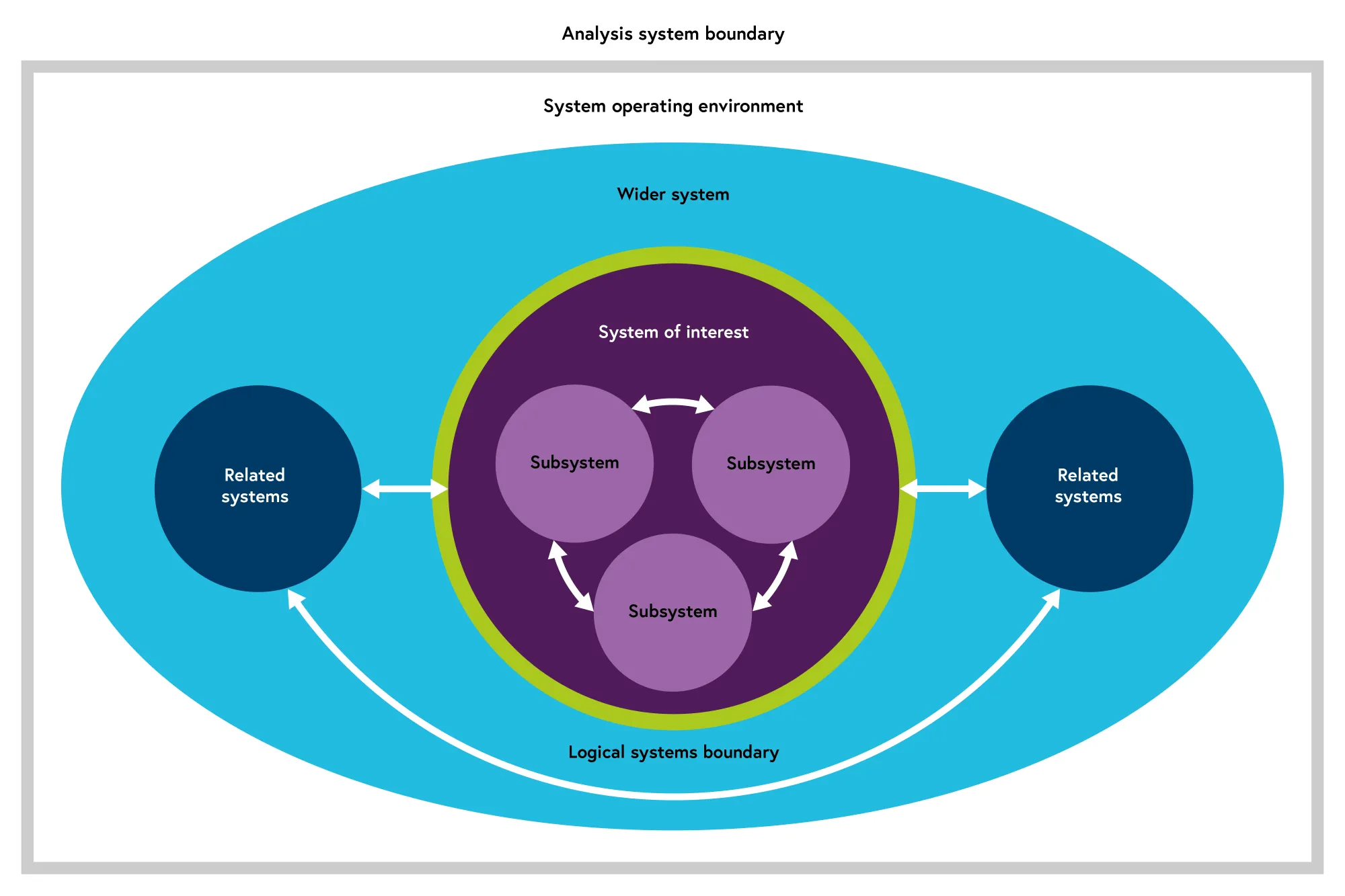

To enable the engineering of complex systems, systems engineers use a variety of principles. For example, a key concept is that of the system boundaries. A system boundary is a line of demarcation between the system itself and its broader context: it divides what is part of the system from what is external to the system. The operating environment or context defines entities that interface with the system but are not within the system boundary.

This concept is illustrated in Figure 1. This definition of systems and their boundaries allows systems engineers to work across different scopes and, consequently, with different boundaries.

Figure 1: System boundary concept. Showing a system of interest, with internal and external interfaces shown as arrows.

In this diagram, a distinction is made between the logical boundary, which defines the direct responsibility of the engineer, and the analysis boundary, which defines the space of what is beyond the engineer’s responsibility but still needs to be considered to carry out effective product or system development.

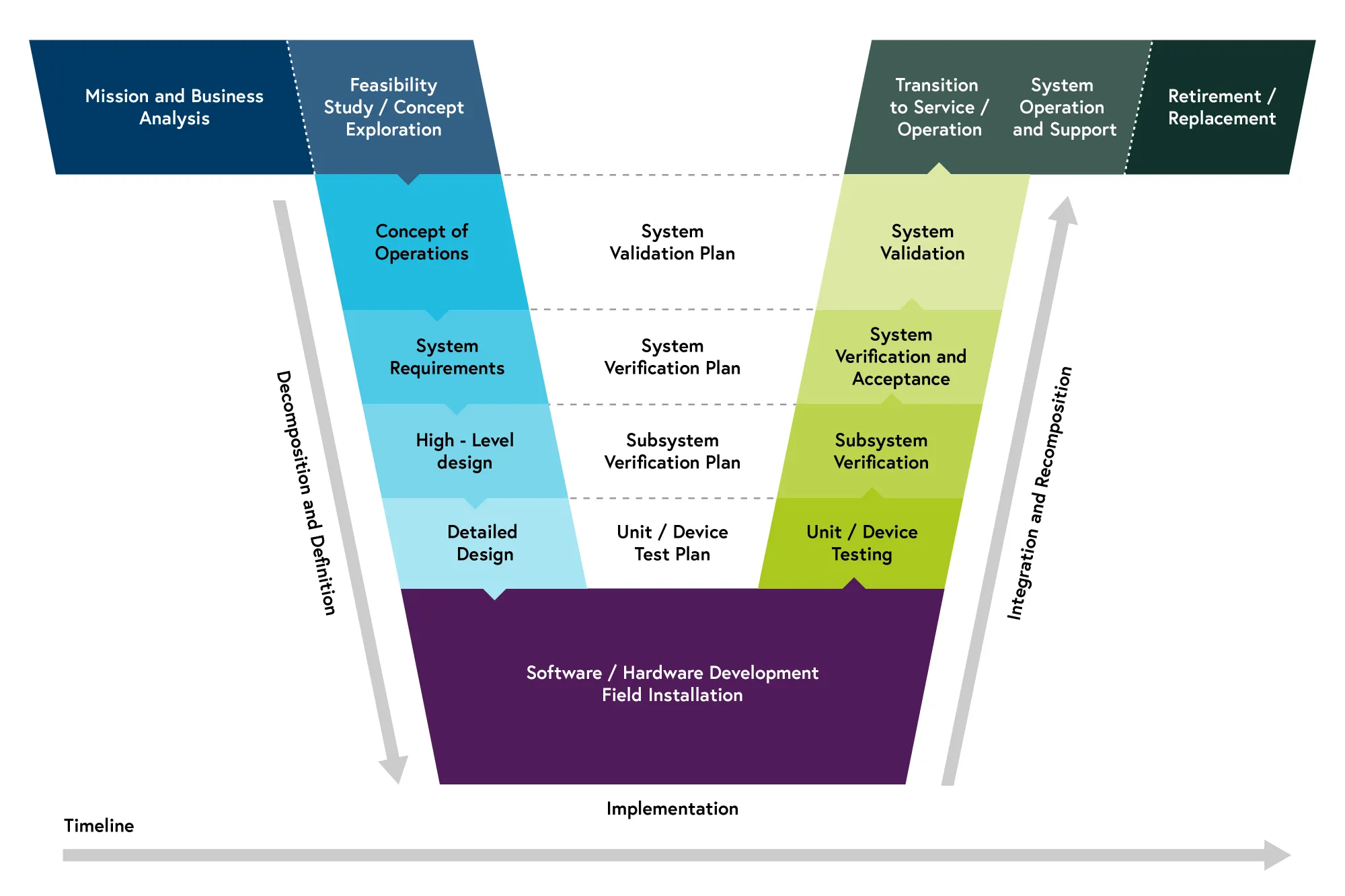

A specific life cycle model might be used to engineer a system like that shown in Figure 1. The most common model for this is often referred to as the ‘V-diagram’ as shown in Figure 2. This shows the sequence of different stages of the systems engineering process and how they are related.

It should be noted that whilst this is the most common approach, others exist and can be categorised as either linear, incremental or evolutionary models. The usefulness of such techniques is not restricted to being used for physical systems but also for systems of systems and services.

It is through the use of these techniques that systems engineering has been used to create things on all scales ranging from microscopic to macroscopic, from creating magnetic artificial cilia with cobalt nanoparticles [10] to building the International Space Station [11].

Systems engineering methodology (V-diagram). The V-diagram shows all stages of the systems engineering process starting with identifying the concept and requirements, through to design, development and then on to integration, verification and validation. It is through the use of models such as these that systems engineers are able to effectively manage the life cycle of a system.

NOTE: It should be noted that the V-diagram can be used both as a wiring diagram (defining dependencies between processes) and as a lifecycle model (a linear interpretation of progression through lifecycle processes).

References

We’re upgrading our systems, and this includes changes to our customer and member account log in, MyIET. It’s part of our big picture plan to deliver a great experience for you and our wider engineering community.

Whilst most of our websites remain available for browsing, it will not be possible to log in to purchase products or access services from Thursday, 17 April to Wednesday, 30 April 2025. Our Member Relations team is here to help and for many of our services, including processing payments or orders, we’ll be able to support you over the phone on +44 (0)1438 765678 or email via membership@theiet.org.

We apologise for any inconvenience this may cause and thank you for your understanding.

For further information related to specific products and services, please visit our FAQs webpage.